Another choke and kill manifold project has just been completed by RBV Energy this time a replacement for a platform in the North Sea.

Front end design

The original choke and kill manifold on our clients platform was installed in 1992 and they were looking to upgrade and replace it. Due to the location of the manifold on the platform it was not possible to remove the entire skid and replace it with a new manifold. We therefore worked closely with the clients engineering and QA team to work out the best way to only replace the choke valves, gate valves, blocks and spools.

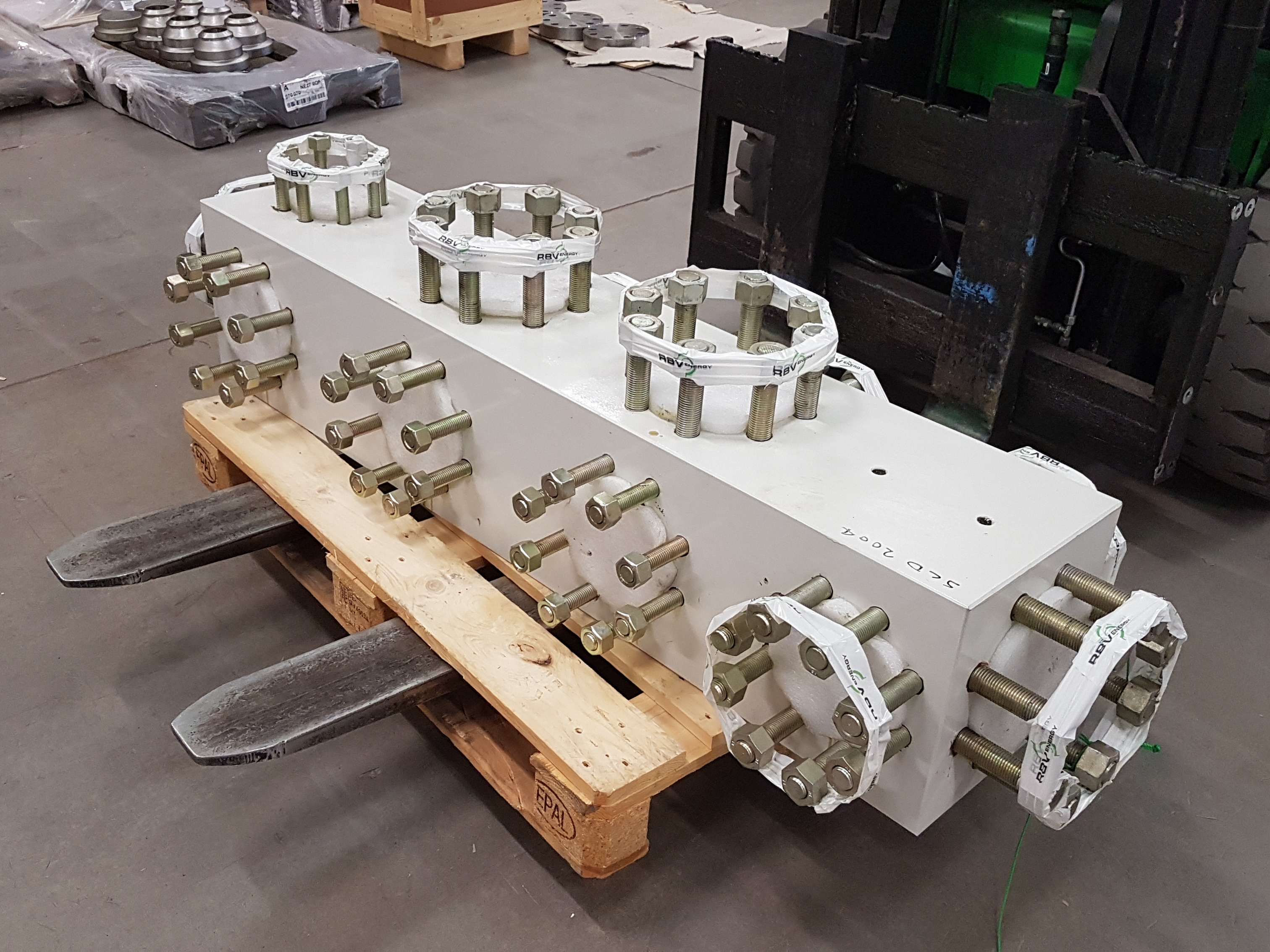

Fabrication and supply

Following the satisfactory conclusion of the detailed engineering, RBV energy proceeded with the manufacture and supply of the replacement piping and valves. Most of the piping items were bespoke and had to fit exactly with both the clients existing pipework and incorporate changes the client made to sizes and pressure ratings.

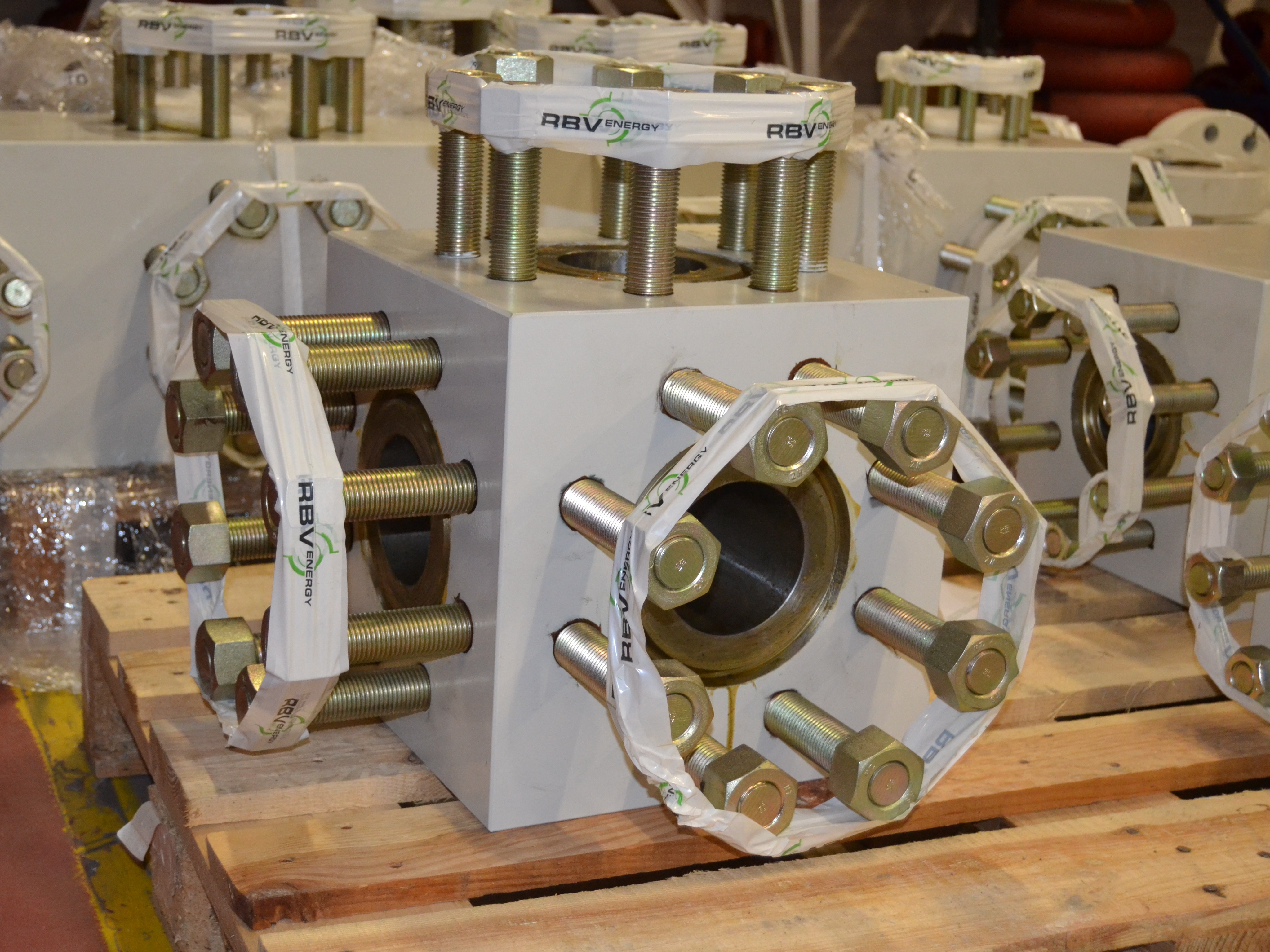

Buffer Chamber

As with all choke and kill manifolds the buffer chamber is integral to the entire system and requires detailed engineering. RBV Energy managed to overcome difficulties with a number of different connection types the client had as well as the unusual orientation of the block itself on the platform. The buffer chamber RBV Energy manufactured was fully in accordance with the latest edition of API 16C and included Inconel 625 inlay to the RTJ grooves.

Please contact us today for any assistance you may need with your replacement manifold projects.