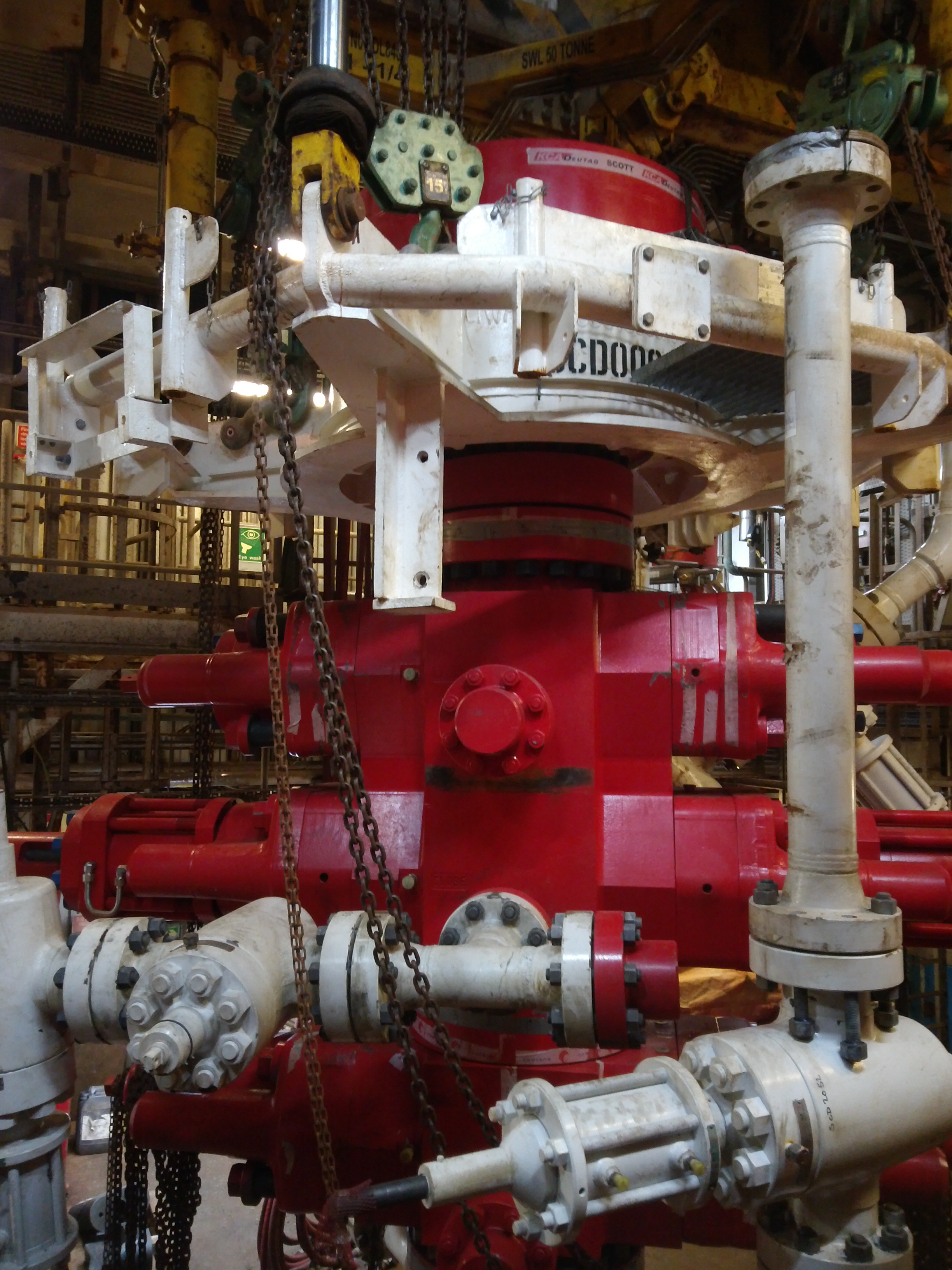

RBV Energy have recently completed the supply of replacement high pressure choke and kill lines for a BOP upgrade for an operator in the North Sea. We worked with our client over a number of months assisting from the design stage all the way through to installation.

Design

We were initially approached by our client with regards to a replacement choke and kill manifold which we helped to supply and install. Our client was also replacing choke and kill spools which ran from their BOP to their choke and kill hoses. The client changed the end connections on their BOP from hubbed to flanged and therefore wanted to change out all of the spools and valves to suit

Fabrication

As we keep a large range of 4130 pipe, API flanges and manifold fittings all suitable for high pressure service we were able to quickly fabricate the bespoke spools to suit our clients new layout.

Quick Connect Fittings

In addition to the replacement piping our client needed a solution for a quick connector for their BOP hoses. RBV Energy managed to provide a comprehensive solution for the client allowing them to connect and disconnect their hoses quickly and saving critical time during operations

Installation

During the installation of the new pipework our client brought to our attention some clashes with their existing structure. We worked with our client to quickly identify the source of the problem and resupplied one of the pipespools. We managed to do this by modifying a spool, rather than fabricate a new one, saving both cost and time for our client.

Despite unforseen delays due to COVID-19 we still managed to deliver the piping and valves within the timeframe the client expected.

For any assistance with similar piping projects, from design to supply, please contact us today.